- Your cart is empty

- Continue Shopping

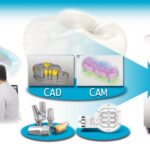

3D CAD-CAM dental prosthesis: 2min find out everything.

How does the 3D printing process of a dental prosthesis work Dentsma?

The stages of a 3D printing process

After receiving the dental impression (here in alginate corresponding to the traditional method, the process presented is also compatible with a digital workflow), the dentsma prosthetist will scan your dental impression.

The design of the 3D model follows, which, once validated, goes into printing in our ProMaker LD10 Dental Models machine from Prodways. This 3D printer is renowned for its production speed as well as for its high-reliability rendering. The printed model goes through a post-process comprising a cleaning step, then polymerization.

Once this step has been carried out, the digital impression is used by dentsma prosthetists in order to design in CAD / CAM the dental prosthesis (s) expected by the dentist and to give them the most natural appearance possible with regard to the constraints of the patient case. paying particular attention to occlusion and contact points. This passage in our computer-aided design and manufacturing center, created in the 2000s, allows us to offer you, from the first try-in, a prosthesis perfectly adjusted to your patient’s mouth.

In the case of a monolithic zirconia crown, it will be machined in a pre-tinted zirconia disc (which has a remarkable aesthetic rendering), before passing through a sintering furnace which will give them their mechanical properties and their final resistance.

Our prosthetist’s work lasts on the aesthetic and cosmetic aspects of your dental prosthesis. They will first start by glazing it: the interest of glazing is to give the prosthesis (here a joint prosthesis) additional customization of color as well as a naturally shiny finish. Firing in the ceramic oven will fix the cosmetic attributes defined by our prosthetists. All that’s left is the sanding step: a prerequisite in prosthetic work which finalizes the rendering of the prosthesis and promotes adhesion to dental tissues.

The digital workflow, an opportunity for your prosthetic cases

Dentsma has used additive manufacturing and machining for over 15 years. Our 3D solutions make it possible to manage all your cases carried out by an endo-oral camera. The 3D pole offers you the following products:

- 3D models for orthodontics, joint, assistant and implantology

- Surgical guides

- Positioning keys

- Compression splints

List of type dental lab equipment, product, the material you maybe need for reference.

Pindex dental machine for model production

https://www.dentallabshop.com/2021/02/17/uses-of-dental-pindex-system-in-the-dental-lab/

Most used material, dental lab equipment, tools in laboratory

Advanced dental lab technology in future

https://www.dentallaboratorio.com/dental-laboratory-technology/